Verpackungslinie für serbische Süßwaren

Januar 19, 2021

ECONO-PAK beginnt mit der Fertigung einer neuen Verpackungslinie für einen serbischen Kunden aus der Süßwarenindustrie.

Das Projekt besteht aus einem Kartonierer HK-S zum Verpacken von Keksen sowie einem anschließendem Sammelpacker zum Bilden von Gebinden in einem Wrap-around-Karton. Die Einbringung der Kekse im Schlauchbeutel in die Produktkassette des Kartonierers erfolgt vollautomatisch durch eine Beladezelle mit Robotern. Diese Kombination von Maschinen verarbeitet bis zu 150 Schachteln pro Minute bei drei unterschiedlichen Packschemen.

Der Sammelpacker gruppiert die Schachteln abschließend zu Gebinden von einer Größe von bis zu 48 Stück und verpackt diese. Damit die Schachteln sowohl stehend als auch liegend gruppiert werden können, verfügt der Sammelpacker über zwei unterschiedliche Einläufe, statt wie üblich lediglich einem. Letztendlich überprüft eine Kontrolleinheit die Gebinde auf Vollständigkeit.

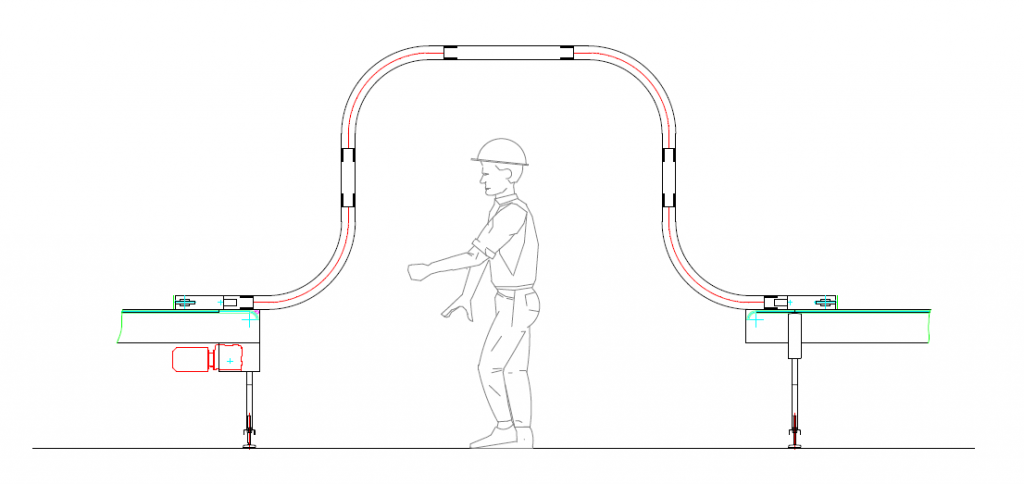

Für eine bessere Erreichbarkeit aller Bereiche erhält die Linie ECONO-PAK-Klemmförderer. Dadurch wird eine Treppe für Mitarbeiter überflüssig und die Arbeitssicherheit erhöht.