Customized, Flexible and Reliable – ECONO-PAK Sleevemachine in operation world wide

October 18, 2016

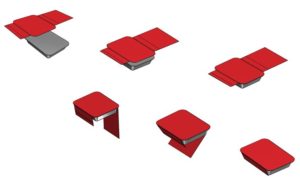

ECONO-PAK provides beside Top-Load, Side-Load and Case Packing also customized system solutions for carton-sleeves. A lot of well-known customers belonging to the food industry already use ECONO-PAK Sleevemachines to pack their product precisely. Especially convevience products in trays are equipped with carton-sleeves. There are different types of sleeves to be processed, for example as half- or full-covered sleeve or with and without standing edge. ECONO-PAK has developed perfect machine solutions for both sleeve designs.

ECONO-PAK Sleevemachine – Mode of Operation

The ECONO-PAK Sleevemachine is designed to automatically sleeve products. The carton-sleeve is designed in such a way that the glue flap is inside.

The carton-sleeves are taken off the blank magazine by a rotary blank feeder and placed in running direction on the product supplied by the conveying system. Products and blanks are placed in such a way that the blanks can be formed in exact U-shape around the product. With the help of form-fit upper and side chains the sleeves are firmly secured and the short glue flaps can be bent and subsequently glued. Due to the thorough fixation of the blank in the machine, a distortion of the glue flaps is minimized to a very high extent and an optimal product display is guaranteed.

The carton-sleeves are taken off the blank magazine by a rotary blank feeder and placed in running direction on the product supplied by the conveying system. Products and blanks are placed in such a way that the blanks can be formed in exact U-shape around the product. With the help of form-fit upper and side chains the sleeves are firmly secured and the short glue flaps can be bent and subsequently glued. Due to the thorough fixation of the blank in the machine, a distortion of the glue flaps is minimized to a very high extent and an optimal product display is guaranteed.

The modular design of the ECONO-PAK machines allows to realize customer requirements customized and flexible, for example with regard to capacity / output of packed products. Thus ECONO-PAK sleevemachines are successfully used in companies based amongst others in Germany, Spain, France and Poland.